Machine Type: Automatic liquid soap making machine, machine for liquid soap production

Power: 25 kW, 380 V, 50 HZ.

Warranty: 1 Year ,Key Selling Points: Competitive liquid soap mixer machine price

Capacity:1000-10000kg/h

Process Type: liquid soap machine ,liquid detergent making machine,

PACKING:Wooden Case

The first-stage pretreatment system: It uses a quartz sand multi-media filter, the main purpose of which is to remove the sediment, manganese, rust, colloids, mechanical impurities, suspended matter and other particles in the water that are more than 20UM and harmful to people. The automatic filtration system uses an imported controller. At the same time, the equipment has a self-maintenance system.

Second-stage pretreatment system: Use activated carbon filter to remove pigments, odors, and a large amount of biochemical organic matter in the water, reduce the residual chlorine value in the water, pesticide pollution, and other pollutants harmful to the human body. The automatic filtration system uses imported controllers, which can automatically perform a series of operations such as backwashing and forward flushing.

The third-level anti-scaling system: Use anti-scaling agents to soften water, mainly to remove the hardness in the water.

Fourth-stage pretreatment reverse osmosis system: A 5-micron pore size precision filter is used to further purify the water, so that the turbidity and color of the water are optimized.

The fifth stage follows the fourth stage reverse osmosis system.

Sixth-level EDI purification device: To ensure the quality of urea ultrapure water that meets the current National VI Standard, EDI devices are essential; EDI is a pure water manufacturing technology that combines ion exchange technology, ion exchange membrane technology, and ion electromigration technology.

2. 1T reactor stirring tank (electric heating)

The reactor is composed of the reactor body, reactor cover, stirrer, transmission device, shaft sealing device, support, etc. When the stirring device has a large height-diameter ratio, multi-layer stirring blades ( folding blade type) can be used, or it can be selected according to the user's requirements. Thickness National Standard 3mm Stirring motor 1.5KW Diameter: 1200mm Height: 2600mm,

3. 5T reactor stirring tank (electric heating) (with liquid level controller)

Thickness: National Standard 3mm Upper stirring motor: 5.5KW Stirring paddle type Folding blade type Diameter: 2000mm Height: 3000mm

4. 15T reactor stirring tank

Including cleaning nozzle (rotating), level gauge, thermometer, manhole and pipe openings; 304 stainless steel material,

The liquid level meter adopts quartz tube + protective sleeve. The bottom of the stirring shaft is fixed. The feed inlet adopts the wall-attached type. The feed thickness is 8mm, and the frequency conversion motor is used . The stirring is a weighted paddle type folding blade three-layer, and the stirring motor is 7.5KW.

5. 5T water storage tank

Mirror stainless steel, steam heating with inner coil, manhole and pipe opening diameter: 1900mm height 2600mm

6. 6T water storage tank

Mirror stainless steel manhole and pipe openings diameter: 2050mm height 2600mm

7. 5T water storage tank

Mirror stainless steel manhole and each pipe opening diameter: 1900mm height 2600mm

8、9.10 Six-head filling line ( with automatic liquid level control and liquid replenishing tank)

The whole machine adopts integrated design, using PLC, photoelectric, touch screen and other high-quality components, the system is easy to operate and adjust, human-machine interface, and adopts novel automatic control technology to achieve higher precision filling.

1、 Features

l Large filling range, high filling accuracy, compact structure. The filling volume is adjusted by actual measurement correction method, digital display control. Easy to operate, clean and maintain, low maintenance cost.

l The new filling head designed by ourselves can effectively prevent dripping and realize defoaming filling with adjustable umbrella. The positioning control system can effectively prevent photoelectric miscounting. Stable diving and effective positioning of the bottle mouth.

l Adopt frequency conversion pump to control flow rate, single filling with single frequency conversion pump and single flow meter, both viscous products and thin products can be filled, with more functionality, more accurate filling quantity, anti-drip and anti-corrosion.

l Consider the wastewater discharge device when cleaning the pipes and filling heads after filling is completed to ensure the normal operation of the filling machine during the next filling.

Technical parameters:

Filling capacity: 500-25000ml Working power: 50HZ/60HZ

3N-380V ±10% Power consumption: 3kw

Automatic capping machine + capping machine

Made of thickened stainless steel, with a climbing cover, it can be customized according to different bottle cap requirements of customers

Main technical parameters:

1. Seal build head Number: 4 2 , life Produce able Capacity: 1500 bottles / hour

3. Suitable use bottle Height: 120mm-320mm 4. Suitable use bottle Diameter: Φ50mm-Φ100mm

5. Bottle cap diameter: Φ22mm-Φ32mm 6. Applicable use bottle Cover: Plastic cover

7. Merit Power: 0.75kw 8 , external shape ruler Size : 1200*1000*2100

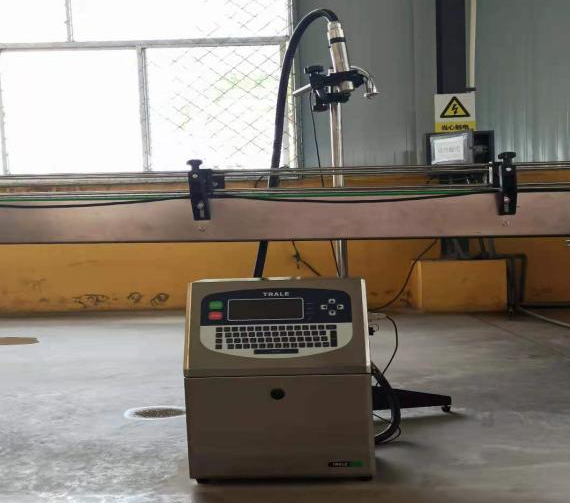

11. Automatic inkjet printer

Speed can reach 75m/min, maximum printing height 12.7mm, maximum resolution 600DPI, can print on metal, plastic, wood, aluminum foil, carton, etc. 450*390*520(mm) Power 0.3KW

12、Double-sided labeling machine

Product range of equipment power and output

Voltage: AC220V 50HZ

Total power (power consumption): 1 hour ≤ 1.2 kW

Production output: 1-90 bottles/min (speed can be adjusted according to product diameter)

Labeling accuracy: ±1 mm (depending on the overall regularity and flatness of the product)

Applicable product range: diameter φ20-φ180 mm (other sizes need to be specially customized)

Qualification rate: ≥97% or more

Overall dimensions of the equipment: 3000X1000X800 mm (length x width x height)

Equipment net weight: ≤300KG

Partial parts names and uses:

(1) The paper tray is made of plexiglass and is a label placement platform for the roll wrapper.

(2) The paper receiving tray is made of plexiglass and has a label waste paper collection device.

(3) The cylinder mechanism is an optional mechanism, which is specially added for bottles with one label on three sides. When the product with one side labeled is transported to the cylinder mechanism position, the cylinder action pushes it to the side, and the brush and sponge wheel smooth the label.

(4) The main board is made of aluminum alloy and is used to install all labeling devices, including label pulling, belt guide, paper feeding, paper collection and main machine lifting and lowering mechanisms.

(5) The main part of the touch screen labeling system is connected to the PLC data inside the chassis. Its function is to control all labeling actions, including production output and labeling signals, etc.

(6) The correction mechanism is made of aluminum alloy and other materials, including the correction motor (1:7.5 60W variable frequency motor) correction mainboard and other important mechanisms. Its main function is to position the product, correct it to the same direction for labeling, and ensure the accuracy of the labeling position.

(7) The conveying motor is a 1100W variable frequency motor, and its main function is to operate the conveyor belt.

(8) The conveyor chain plate is 101.6 mm wide and made of PVE engineering plastic, used for transporting products.

(9) The label pulling mechanism is mainly composed of important accessories such as the label pulling motor, the label pulling driving wheel, the embossed aluminum wheel, etc., which is the main core mechanism for peeling the label off the base paper.

13、Automatic feeding machine

Automatic stainless steel spiral feeder

The feeder is made of high-quality stainless steel. The spiral feeder uses rotating spiral blades to push urea granules into the spiral conveyor for transportation. The force that prevents urea granules from rotating with the spiral conveyor blades is the weight of the urea granules and the friction resistance of the spiral conveyor casing to the urea granules. The contact parts between the spiral blades welded on the rotating shaft of the spiral conveyor and the urea granules are all made of high-quality stainless steel to ensure that the urea granules are not contaminated. It has a high degree of automation and is easy to operate, which greatly reduces the labor intensity of the operator.

Length*width*height: 1000*6600*2500mm