Principle of horizontal mixer:

A single -layer S-shaped spiral blade is arranged on the transmission main shaft of the horizontal mixer. The outer blade conveys the material to the middle, and the inner blade conveys the material to the outside. The material is driven by the double-layer spiral to form a low-power and efficient mixing. In the environment, the inner and outer diameter spirals installed on the mixing shaft drive the materials in the barrel, so that the agitator can turn the materials in a large range in the barrel. When the stirring device is working, the inner spiral drives the material near the axis to rotate. The axial direction is pushed from the inside to the two sides, the outer spiral drives the barrel wall material to make the axis rotation, and the axial direction is pushed from the two sides to the inside, the mixture can be uniformly mixed in a short time

|

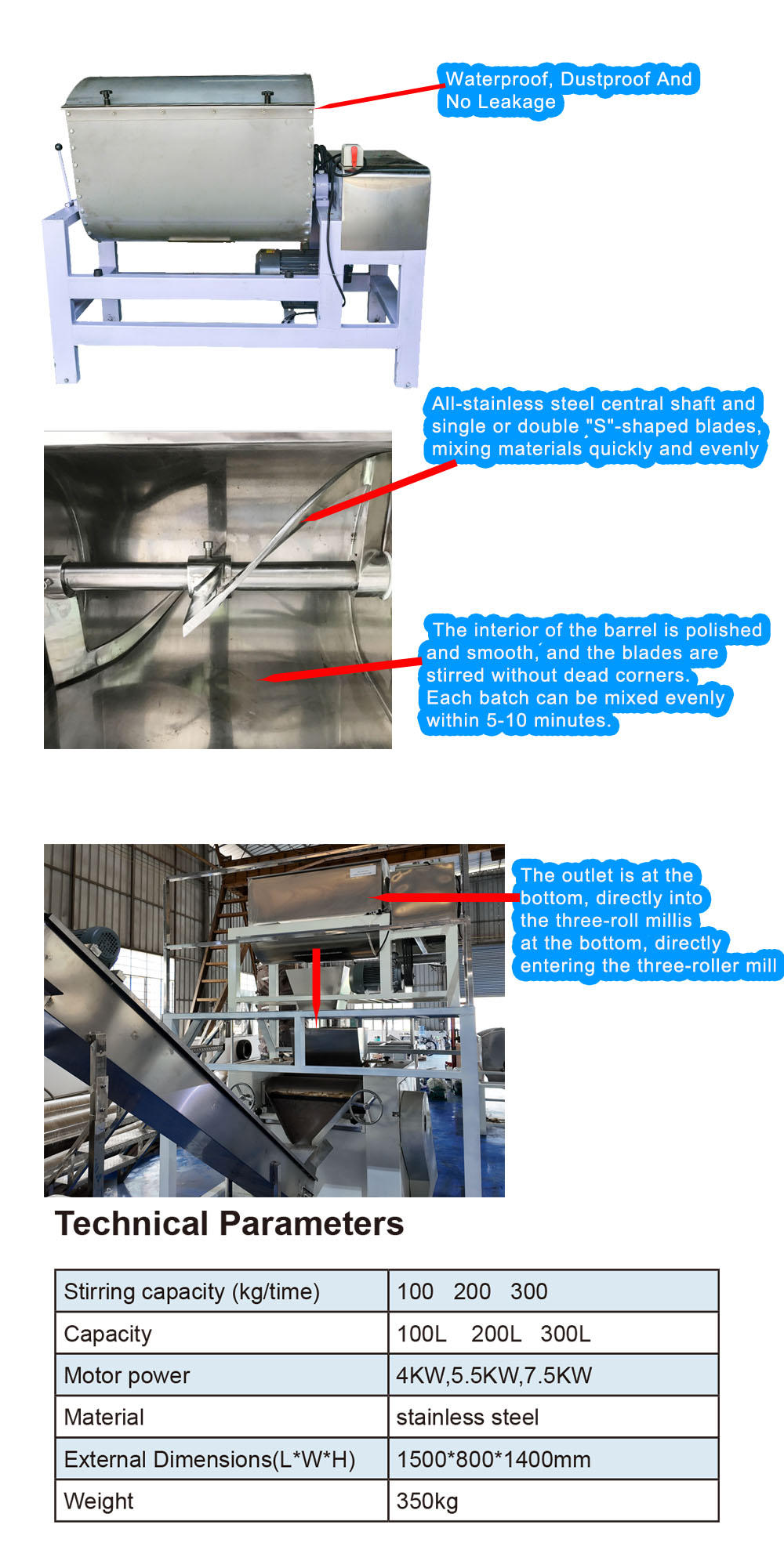

Performance parameters:

1. The equipment is made of carbon steel (iron), and the material contact surface is stainless steel.

2. The mixing capacity :100L,200L 300L

3. The interior of the barrel is polished and smooth, and the blades are stirred without dead corners. Each batch can be mixed evenly within 5-10 minutes.

4. All-stainless steel central shaft and single or double "S"-shaped blades, mixing materials quickly and evenly;

5. Discharge port: manual butterfly valve (with waterproof, dustproof and no leakage.)

6. Power: 4KW,5.5KW,7.5KW

|