I. Brief Instruction:

Automatic toilet soap making machine. Material is soap noodle.

The dimension and pattern of the soap can be made by customer’s requirements.

II. Production Condition:

1. Hotel soap making machine capacity: 0-500 kg/hr.

2. Materials: soap noodle (soap grains), pigment, fragrance.

3. Workshop: above 50 m2 , L: 10 m, W: 5 m, H: 3 m, including operating space, excluding packing machine.

4. Power: 25 kW, 380 V, 50 HZ. 5. Staff: 2-4 persons

MATERIAL: Frame - Q235 carbon steel, the part touched by soap noodle- stainless steel

MIXING TIME: 5min/time

OUTPUT: 100kg/time

MIXING TYPE: “Z”

REVOLUTION: 33 rpm

POWER: 7.5kw

DIAMETER OF ROLLER: Φ880mm

OVERALL SIZE: 2300×842×1160mm

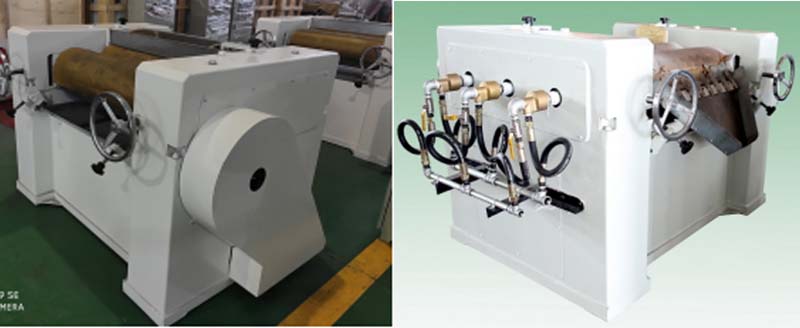

MATERIAL: frame- Cast iron, roller-high Chrome alloy, hardened roll surface

ROLLER DIAMETER:260mm

ROLLER LENGTH:685mm

SPEED RATIO:1:3:9

POWER:11kw

OVERALL SIZE:1670×1450×1100

WEIGHT:About 2280kg

MATERIAL: Q235 carbon steel with stainless steel surface touched by soap

OUTPUT:500kg/h

WORM DIAMETER:Φ204mm

1st REVELUTION:18 rpm

POWER:11kw

2nd REVELUTION:10-18 R/M POWER:15kw

VACUUM PUMP POWER: 1.1kw

With heating device 1kw

OVERALL SIZE:3140×1350×2530mm

WEIGHT:About 4000 kg

OUTPUT:80-120 pcs/min

POWER:3kw(ELECTRIC-MAGNETIC ADJUSTABLE)

WEIGHT:About 2000 kg

SOAP CUTTING:50-200g/pc

OVERALL SIZE:1500×950×1300mm

MATERIAL: cast iron for stand, imported straight guide rail, some parts in 45# steel and copper alloy.

The Advantages of automatic soap making machine

Our automatic soap making machine is at the forefront of innovation, revolutionizing the soap manufacturing process.

Here are the key advantages that set our machinery apart:

1.Efficiency in Production:

Our fully automatic soap making machine is designed for optimal efficiency. It streamlines the entire production

process, from raw material input to packaging, reducing manual labor and maximizing output.

2.Precision in Formulation:

Always achieve precise soap recipes with our small hotel soap making machine production line system. Ensure high soap quality.

3.Cost-Effective Operation:

Customizing machines for soap production with different outputs for different customers is the maximization of customers' profits.

4.Flexibility in Batch Sizes:

We can provide special designs according to the customer's workshop area to make production more convenient for the customer.