I. Brief Instruction:

This soap line is used to produce laundry soap bar and toilet soap bar starting from materials oil and caustic soda. Capacity is 500~800 kg/hr.

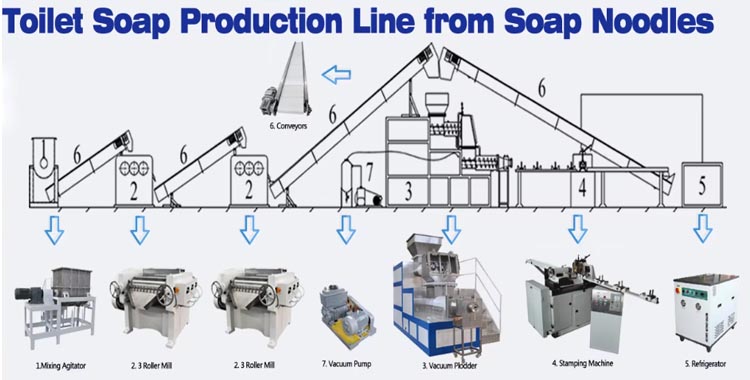

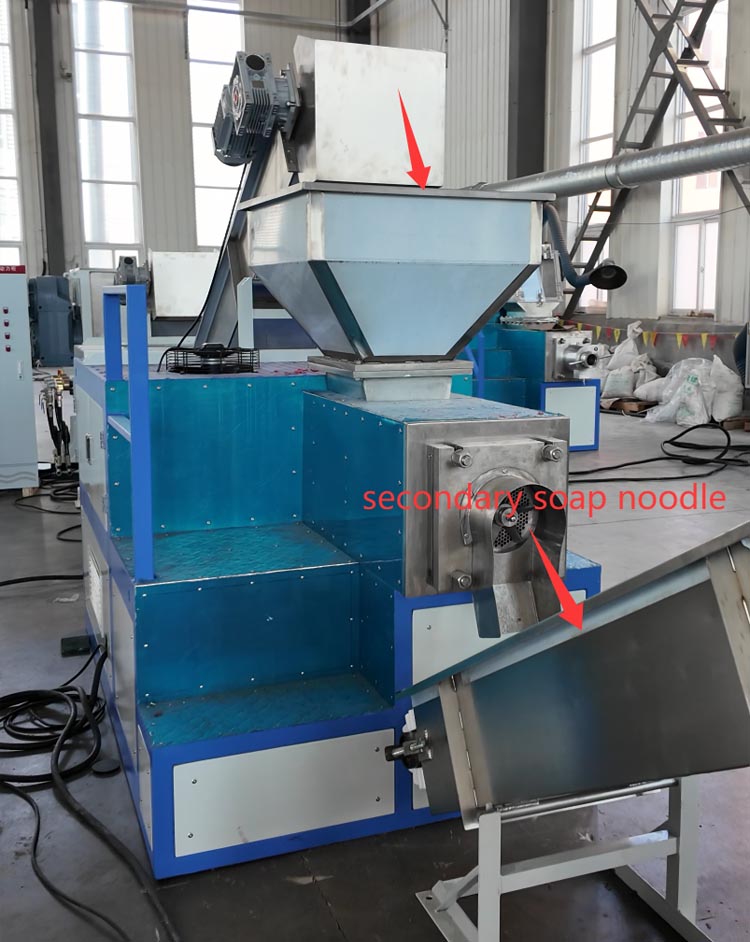

Basic process is to put the oil and soda lye into the saponification tank with automatic mixer and then discharge out the liquid soap base out to wait for drying naturally. Collect the dried soap blocks and put into the fully automatic finishing production line, including mixer, three roller mill, vacuum plodder, and stamping machine. The dimension and pattern of the soap can be made by customer’s requirements. Main machines are made of stainless steel.

II. Production Condition:

1. Capacity: 500 kg/hr

2. Workshop: above 30 m2, L: 30 m, W: 10 m, H: 3.5 m.

3. Power: greater than 115 kW, 380 V, 50 HZ.

4. Staff: 6 persons.

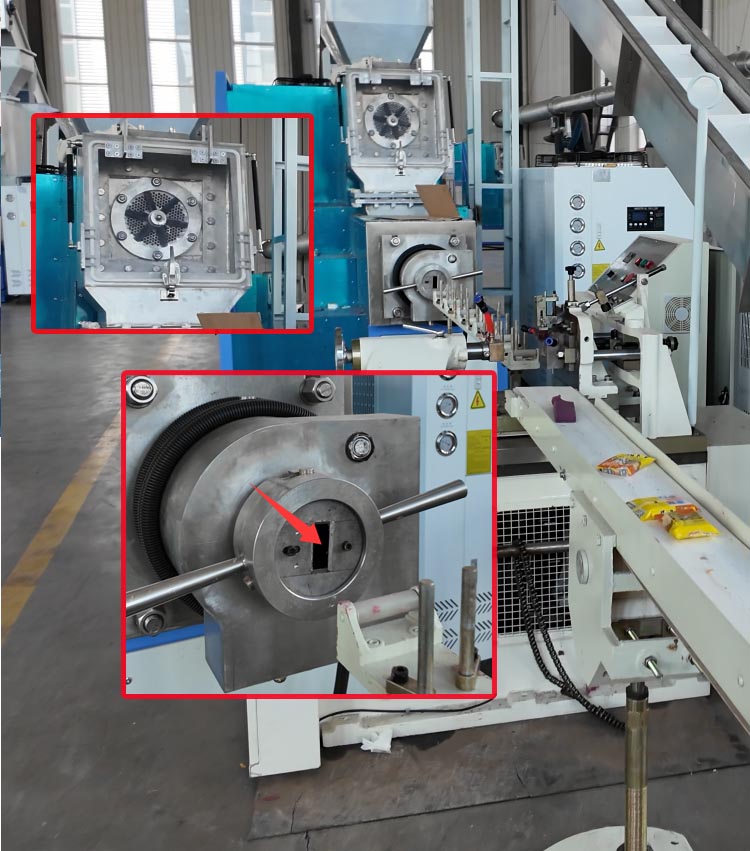

XDA-120 toilet soap stamping machine with liner guide is designed for cooling and stamping the soaps.

This machine together with our vacuum plodder and other machines, compose a complete toilet soap

production line, and the stamping machine can cut, stamp and shape the soap with good-looking at the same time.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

3.what can you buy from us?

soap machine,soap finishing product line,laundry soap machine,toilet soap machine,soap plant

4. why should you buy from us not from other suppliers?

We have more than 20 years experience in the soap and glycerin equipment design and manufacture.

We can give you the finishing product line as turn-key project.

We would give you the best after-sale service on the operation & maintenance of the machine

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,Express Delivery;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,French,Russian