Machine Type: automatic soap making machine, automatic soap machine

Materials: soap noodle (soap grains), pigment, fragrance.

Power: 25 kW, 380 V, 50 HZ.

Warranty: 1 Year ,Key Selling Points: Competitive automatic soap making machine price

Capacity:100-3000kg/h

Process Type: automatic toilet&laundry soap making machine

PACKING:Wooden Case

Automatic toilet soap making machine and packing machine

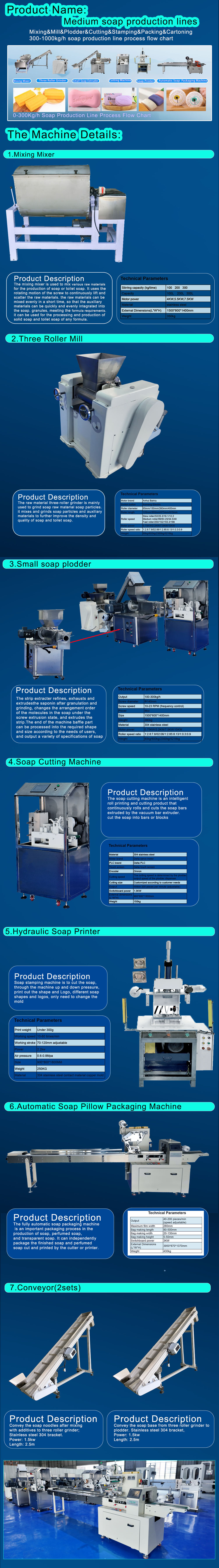

soap mixing machine - soap lift conveyor - soap three roll mill - soap lift conveyor - soap dispenser/ sosp extruder/soap plodder - soap cutting machine - soap stamp machine - soap package machine

1. Design description:

This set of production line is a soap forming production line with soap nuggets as raw materials. After raw material mixing, grinding, vacuum stripping, and printing, medium and high-grade soaps with a fatty acid content of 55-70% can be produced. The production line uses a double-layer vacuum stripping machine, which can make the soap structure compact and not easy to crack.

. Production process:

1: Put the soap noodles or soap flakes into the mixer first, start the mixer, and then evenly put in the flavors, pigments, other auxiliary materials, preservatives, etc., after mixing evenly, open the square material valve, put the materials into the silo, wait, and close Mixer.

2: Start the first conveyor and the first three-roll grinder, then open the silo valve, let the material enter the conveyor and send it to the grinder for grinding.

3: After the material enters the double vacuum strip machine, confirm that it can produce continuously, start the first screw, and start the second screw after discharging.

4: After the paper is issued. Start the printer and the fourth conveyor, confirm whether the printing speed and the delivery speed are the same, the good soap is loaded into the tray, and the soap head and the poor entering the conveyor return to the delivery machine.