I. Brief Instruction:

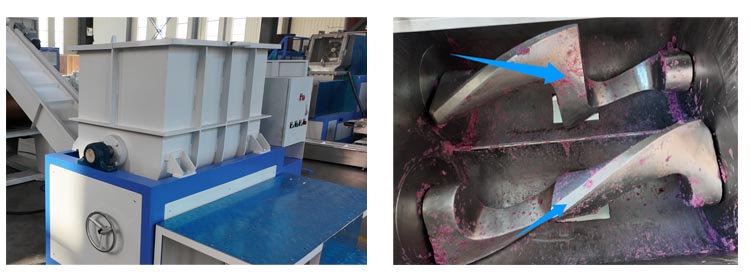

This soap line is used to produce toilet soap with fatty acid content (active matters content) from 60% to 80%. Material is soap noodle. Capacity is 500-800 kg/hr. The dimension and pattern of the soap can be made by customer’s requirements. Parts of mixer and vacuum plodder that would be touched with soap materials are made of stainless steel 304.

II. Production Condition:

1. Capacity:500-800 kg/hr.

2. Materials: soap noodle (soap grains), pigment, fragrance.

3. Workshop: above 110 m2, L: 22 m, W: 5 m, H: 3.5 m, including operating space, excluding packing machine.

4. Power: greater than 60 kW, 380 V, 50 HZ.

5. Staff: 6 ~ 8 persons.

Stamping Machine

The stamping machine is used to cut, shape and print the soap bar extruded from vacuum plodder.This machine can produce round,oval,and quadrate soaps

The Advantages of automatic soap making machine

Our automatic soap making machine is at the forefront of innovation, revolutionizing the soap manufacturing process.

Here are the key advantages that set our machinery apart:

1.Efficiency in Production:

Our fully automatic soap making machine is designed for optimal efficiency. It streamlines the entire production

process, from raw material input to packaging, reducing manual labor and maximizing output.

2.Precision in Formulation:

Always achieve precise soap recipes with our small hotel soap making machine production line system. Ensure high soap quality.

3.Cost-Effective Operation:

Customizing machines for soap production with different outputs for different customers is the maximization of customers' profits.

4.Flexibility in Batch Sizes:

We can provide special designs according to the customer's workshop area to make production more convenient for the customer.