I. Brief Instruction:

Automatic hotel soap machine. Material is soap noodle.

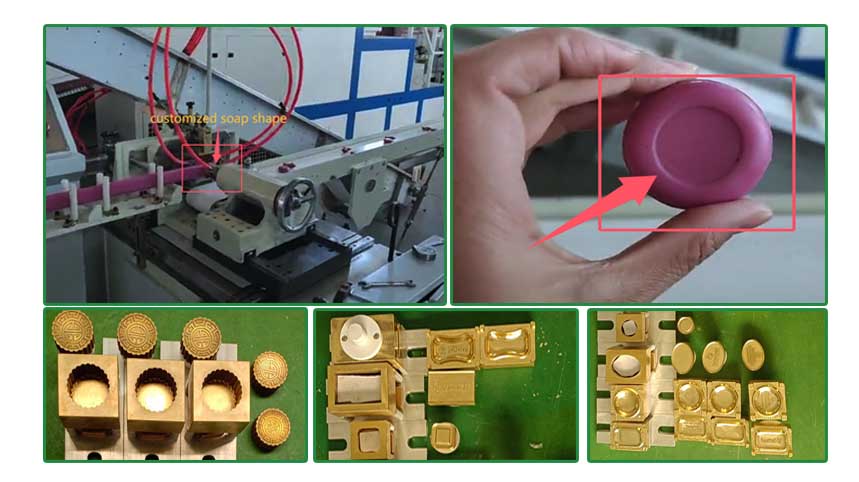

The dimension and pattern of the soap can be made by customer’s requirements.

II. Production Condition:

1. Hotel soap making machine capacity: 100-3000 kg/hr.

2. Materials: soap noodle (soap grains), pigment, fragrance.

3. Workshop: above 50 m2 , L: 10 m, W: 5 m, H: 3 m, including operating space, excluding packing machine.

4. Power: 25 kW, 380 V, 50 HZ. 5. Staff: 2-4 persons

Automatic hotel soap making machine,Hotel soap machine with different outputs can be designed.For example,mini soap making machine for hotel,

small hotel soap making machine production line so.

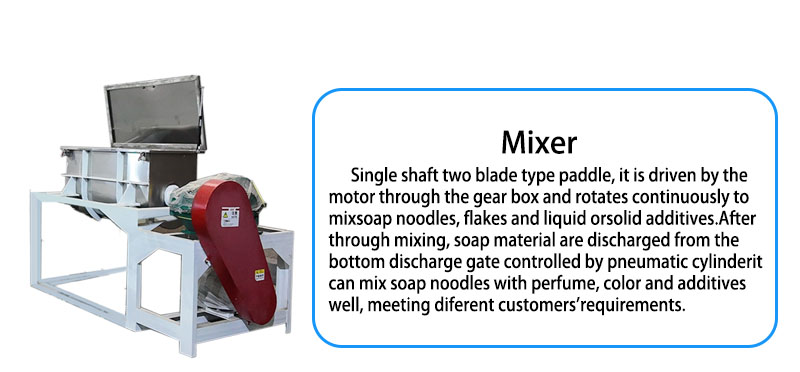

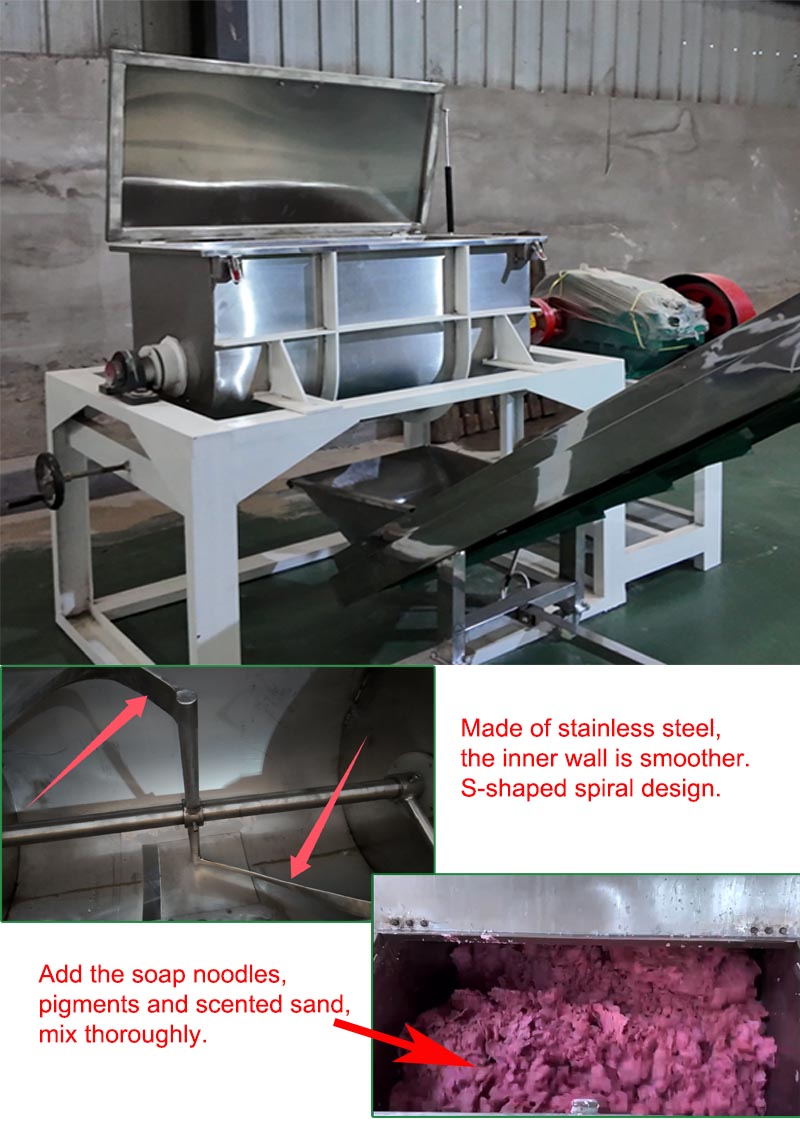

This part is the first link of machine for hotel soap production,machine to make hotel soaps -----mixer.

It is used to make the soap particles and additives mixed more evenly, the soap body structure is tight, and

the density and quality of the soap body are improved!It is important part with hotel soap making machine.

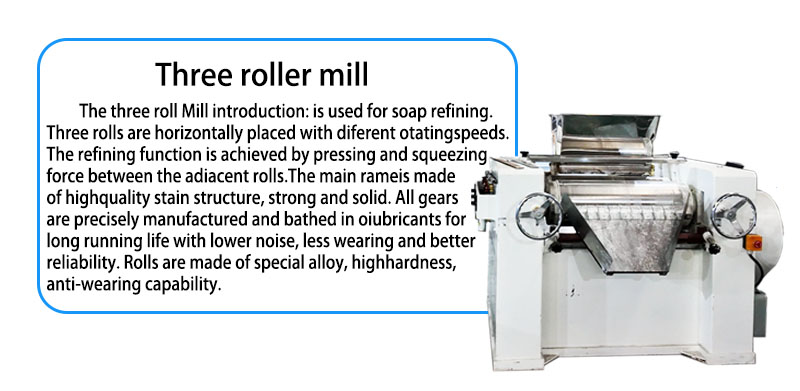

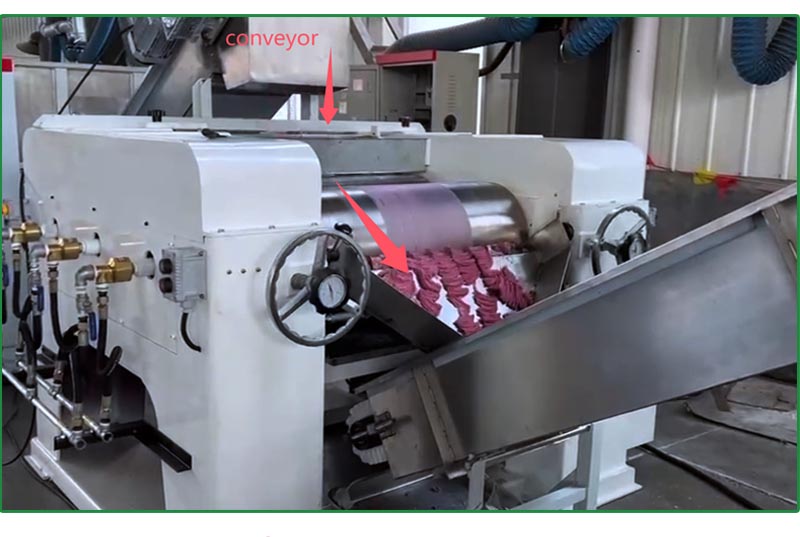

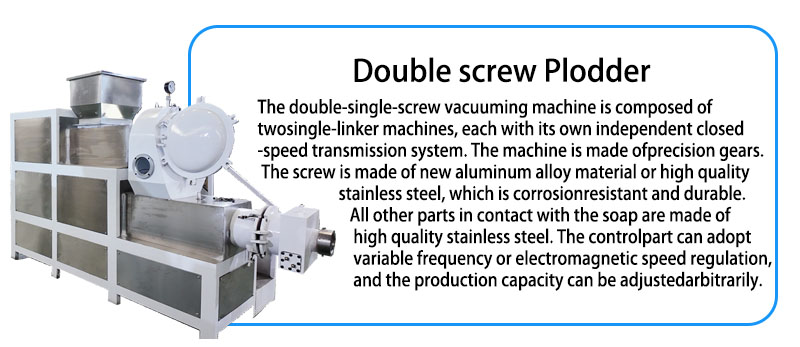

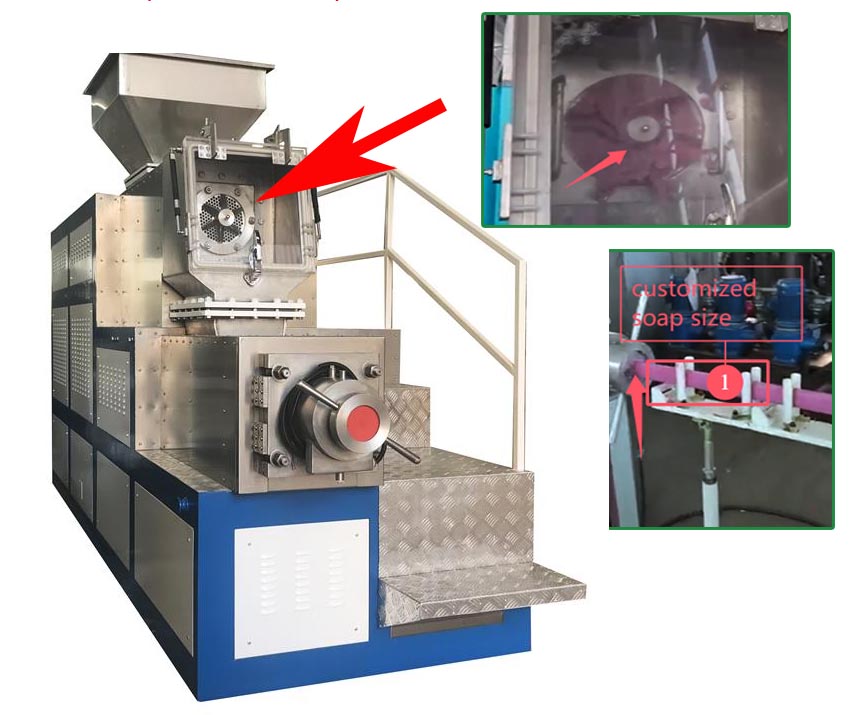

The soap base is squeezed and refined to make the soap bar structure dense and the surface smooth. It becomes soap block.

This part is the key part of the machine to make hotel soaps.

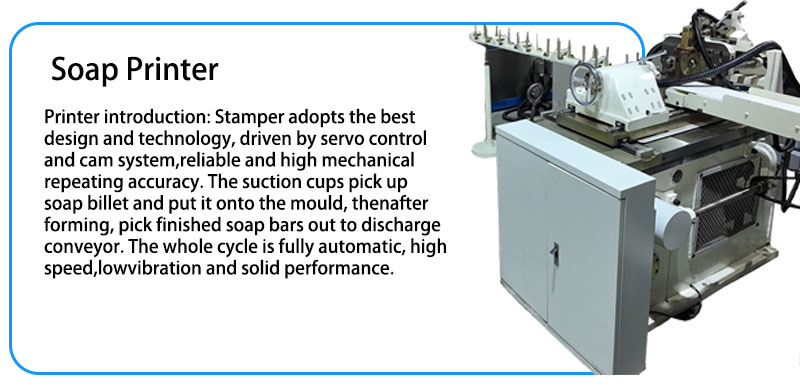

This part of the hotel soap making machine is to print the soap into the shape and logo you want.

The last part of Industrial hotels soap making machine is automatic hotel soap wrapping machine.

Here is the most advanced and convenient hotel soap wrapping machine.

The Advantages of automatic hotel soap making machine

Our automatic hotel soap making machine is at the forefront of innovation, revolutionizing the soap manufacturing process.

Here are the key advantages that set our machinery apart:

1.Efficiency in Production:

Our fully automatic hotel soap making machine is designed for optimal efficiency. It streamlines the entire production

process, from raw material input to packaging, reducing manual labor and maximizing output.

2.Precision in Formulation:

Always achieve precise soap recipes with our small hotel soap making machine production line system. Ensure high soap quality.

3.Cost-Effective Operation:

Customizing machines for hotel soap production with different outputs for different customers is the maximization of customers' profits.

4.Flexibility in Batch Sizes:

We can provide special designs according to the customer's workshop area to make production more convenient for the customer.