Use palm oil to Produce Soap continuous saponification plant for laundry bar soap

"a. Steam boiler: 2MT/h, 1.25Mpa.

b. Workshop: more than 300m² Length: 35m, width: 8m, height: 7m.

c. Electricity: about 280kW/h, 380V, 50HZ.

d. Water: Circulating water for vacuum drying system: 15m3 of production water;

2. Materials and onsumption for soap production:

Oil: palm oil, palm stearin, palm fatty acid, palm kernel oil, etc., various vegetable oils and animal fats.

Caustic soda: NaOH 97%-99%. Clean water. Sodium chloride (NaCl).Optional materials: spices, pigments, titanium dioxide, talc, etc.

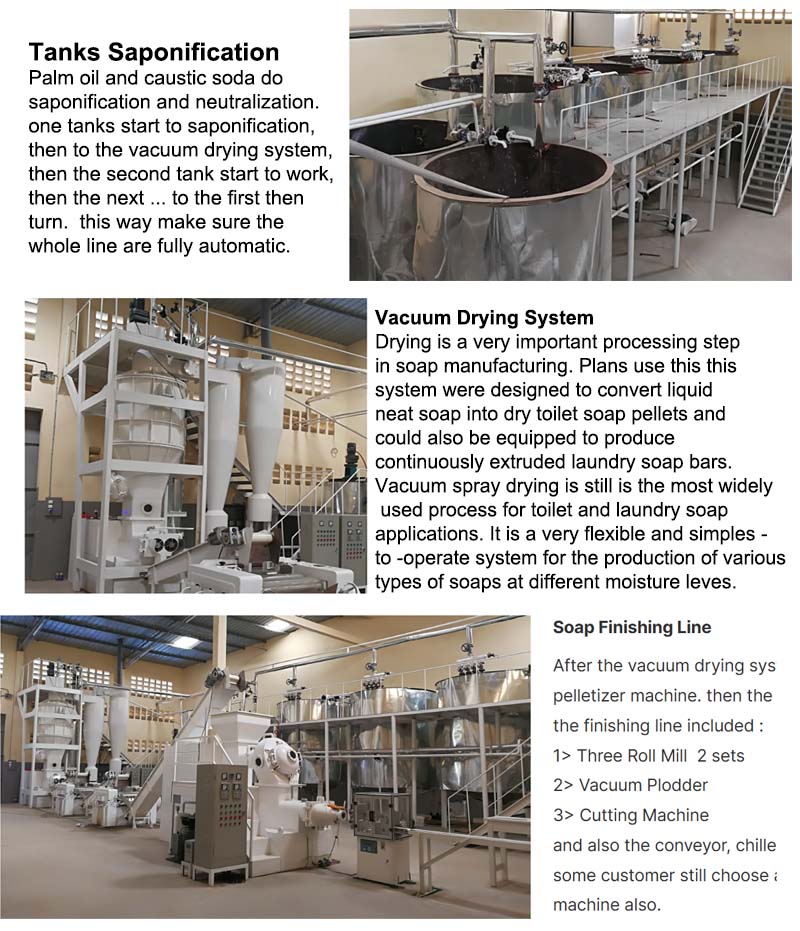

This product line is a laundry soap complete line starting from oil melting, saponifying (no water-draining), vacuum drying

and cooling, milling soap noodles, vacuum extruding and then stamping&cutting into soaps

The Advantages of automatic soap making machine

Our automatic soap saponification machine and soap noodle machine are at the forefront of innovation, revolutionizing the soap manufacturing process.

Here are the key advantages that set our machinery apart:

1.Efficiency in Production:

Our fully automatic automatic soap saponification machine and soap noodle machine designed for optimal efficiency. It streamlines the entire production

process, from raw material input to packaging, reducing manual labor and maximizing output.

2.Precision in Formulation:

Always achieve precise soap recipes with our small soap making machine production line system. Ensure high soap quality.

3.Cost-Effective Operation:

Customizing machines for automatic soap saponification machine and soap noodle machine with different outputs for different customers is the maximization of customers' profits.

4.Flexibility in Batch Sizes:

We can provide special designs according to the customer's workshop area to make production more convenient for the customer.