I. Brief Instruction:

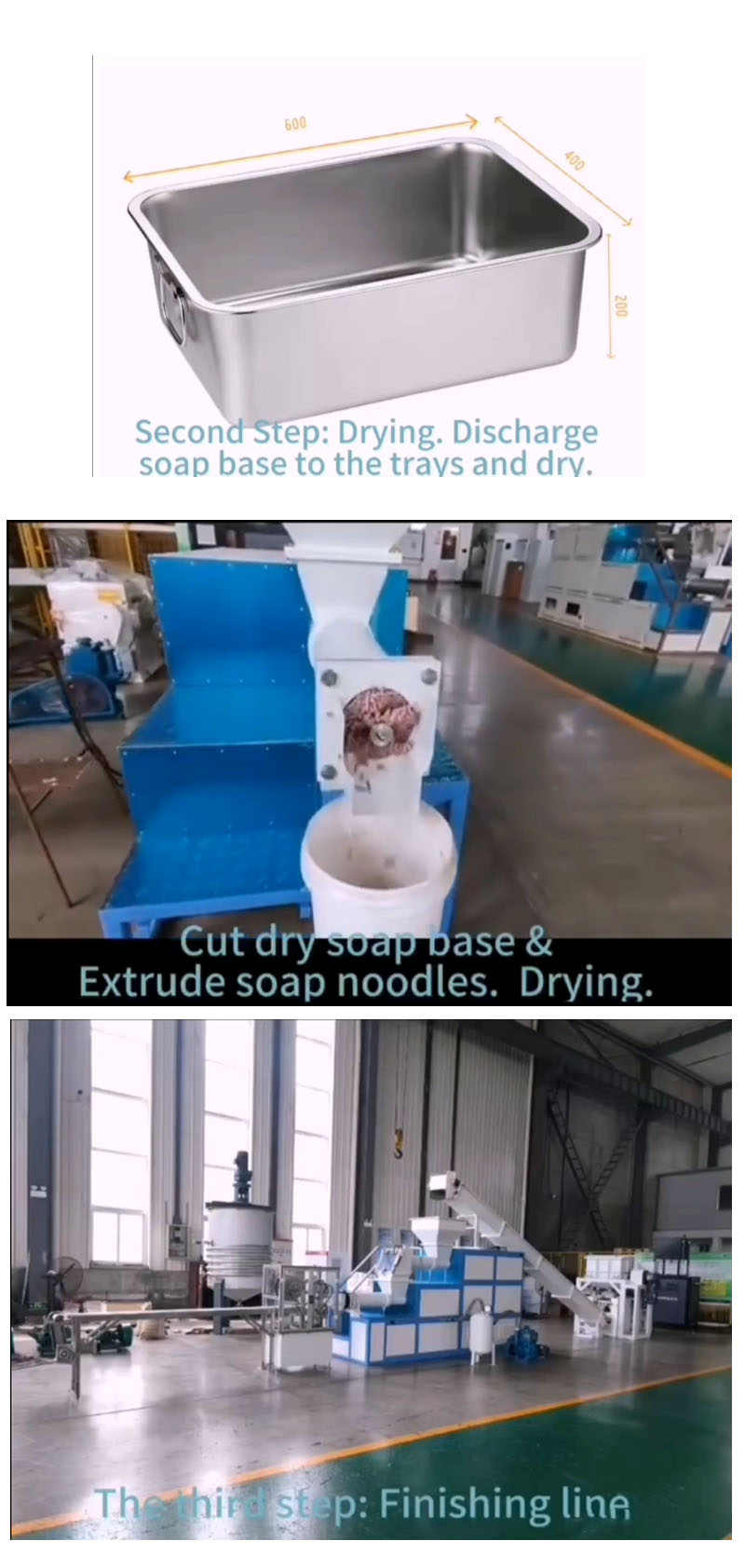

Soap saponification machine for different capacity for soap making machine .Basic process is to put the oil and soda lye into the saponification tank with automatic mixer and then discharge out the liquid soap base out to wait for drying naturally. Then you collect the dried soap blocks and put into the fully automatic finishing production line, including mixer, three roller grinder, vacuum plodder, soap stamping machine, conveyor belts, controllers, etc.

II. Production Condition:

1. saponification equipment Capacity:1000-1500 kg/hr

2. Materials: plant oil (palm oil, palm kernel oil, coconut oil, etc.), caustic soda, pigment, fragrance.

3. Workshop: above 250 m2, L: 25 m, W: 10 m, H: 3.5 m, including operating space, excluding packing machine.

4. Power: greater than 100 kW, 380 V, 50 HZ.

5. Staff: 4-6 persons.

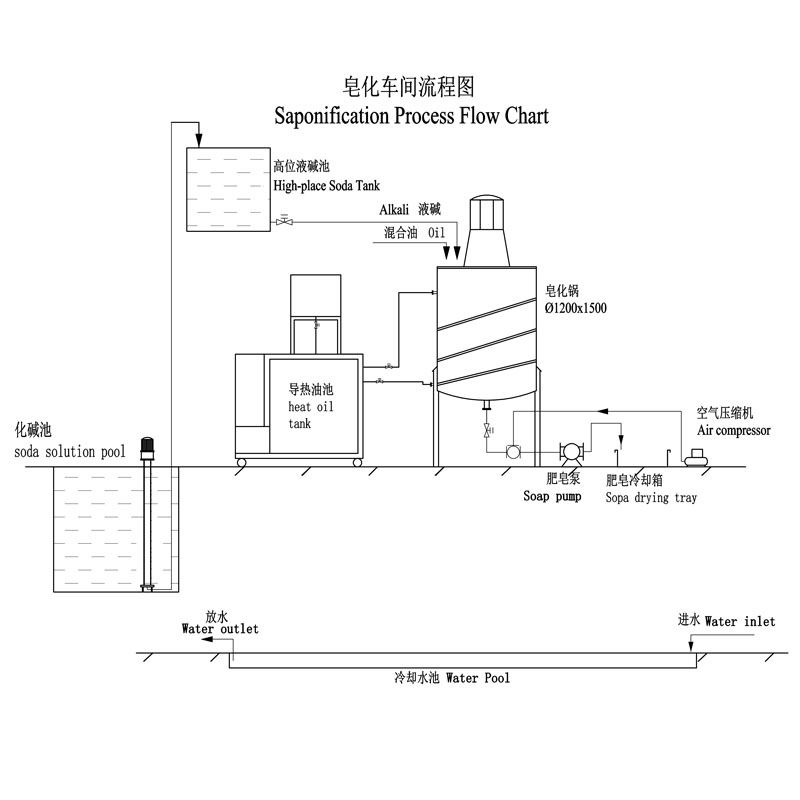

Saponification process flowing chart

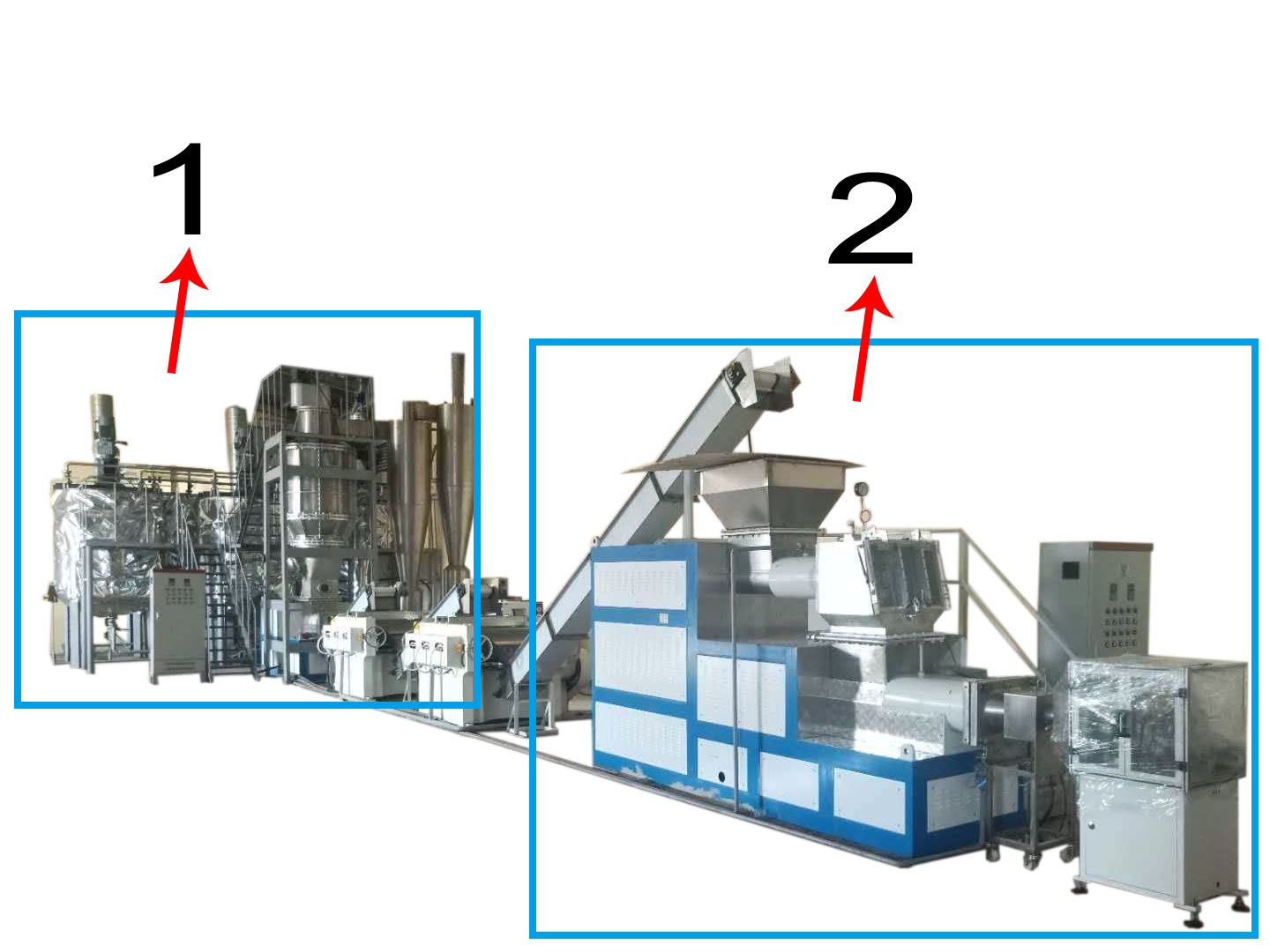

| NO. | Item | Process |

| 1 |

Saponification Process |

1.Oil and caustic soda do saponificatin. 2.Natural drying. 3.Cutting into soap noodles. |

| 2 |

Soap Finishing Line |

1.Mixing all materials; 2.Grinding into pieces; 3.Vacuum extruding soap bar; 4.Stamp logo and cut. |

Saponification plant Oil-melting Tank

Melt and mix all kinds of oil like palm oil and palm kernel oil. User prepare it. Volume: 3 m3. Oil pump Transfer the oil into saponification tank.

Automatic metering oil input. Including oil flow meter and control switch. User prepare it. Power: 3 kW.

Soda-melting Pool

Dissolve caustic soda to soda solution. Including pipes & valves used for this part. Volume: 3 m3.

Soda solution pump

Transfer the soda lye into high placed soda tank. Automatic metering solution input. Including oil flow meter and control switch. Power: 3 kW.

High-placed Soda Tank

1.Size:1 m3.

2. Marked measuring scale.

The Advantages of automatic soap making machine

Our automatic soap making machine is at the forefront of innovation, revolutionizing the soap manufacturing process.

Here are the key advantages that set our machinery apart:

1.Efficiency in Production:

Our fully automatic soap making machine is designed for optimal efficiency. It streamlines the entire production

process, from raw material input to packaging, reducing manual labor and maximizing output.

2.Precision in Formulation:

Always achieve precise soap recipes with our small hotel soap making machine production line system. Ensure high soap quality.

3.Cost-Effective Operation:

Customizing machines for soap production with different outputs for different customers is the maximization of customers' profits.

4.Flexibility in Batch Sizes:

We can provide special designs according to the customer's workshop area to make production more convenient for the customer.